Industrial Coffee Grinder for Bulk Coffee Production: What You Need to Know

Industrial Coffee Grinder for Bulk Coffee Production: What You Need to Know

Blog Article

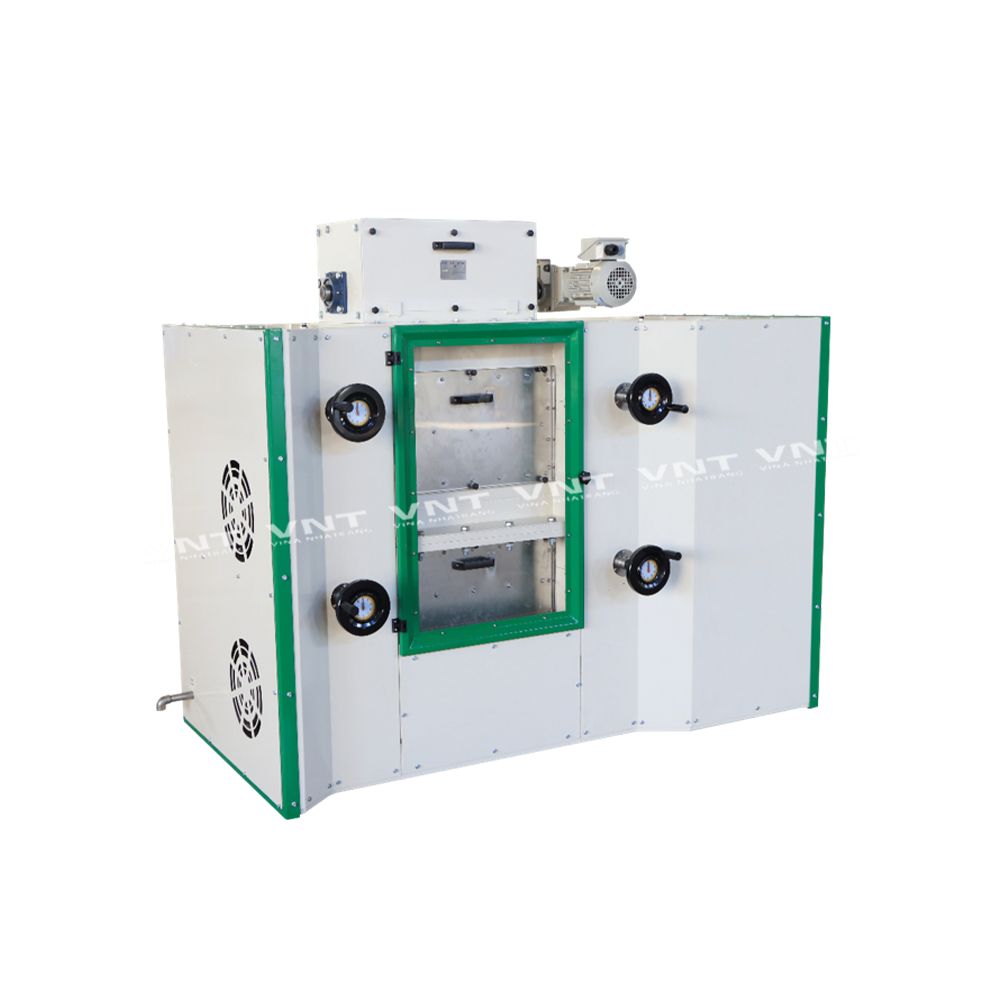

Industrial Coffee Mill Guide: Increase Performance and High Quality

In the affordable landscape of coffee manufacturing, picking the appropriate commercial coffee grinder plays a critical function in boosting both effectiveness and product quality. Recognizing the nuances of various grinder types and essential features-- such as personalized grind setups and robust building-- can substantially affect the final flavor profile of the coffee. The optimization of the grinding process, combined with attentive upkeep, is necessary for sustaining performance over time. As we check out these vital aspects, it comes to be noticeable that the implications expand beyond plain tools option, affecting overall organization success in manner ins which necessitate closer assessment.

Recognizing Mill Types

When picking an industrial coffee grinder, understanding the different types available is crucial for maximizing both taste extraction and operational performance. Both key types of grinders are blade mills and burr grinders. Blade grinders utilize sharp blades that cut coffee beans right into inconsistent dimensions, resulting in unequal extraction and potentially unwanted flavors. While blade grinders are usually more economical and appropriate for small-scale operations, they are usually not suggested for commercial usage.

Inevitably, picking the appropriate kind of grinder is indispensable to keeping high quality and performance in coffee manufacturing, making it imperative for businesses to invest in high-grade burr mills for optimal outcomes.

Secret Functions to Take Into Consideration

Selecting an industrial coffee mill requires mindful factor to consider of several essential functions that can substantially affect both efficiency and the general coffee experience. One of the key elements to evaluate is the grinding device. Burr grinders are usually chosen over blade mills, as they provide a regular work size, which is vital for optimal removal and taste.

An additional vital function is the grinder's capacity. Depending on the volume of coffee you require to procedure, select a design that can handle your needs without compromising speed or high quality. In addition, take into consideration the work setups offered. A functional mill with numerous setups enables you to customize the work size to various brewing methods, boosting the coffee's flavor account.

Assess the mill's noise degree, particularly in an active café or production environment, where too much noise can be turbulent. Spending in a mill that balances these features can significantly boost both operational performance and the quality of the coffee served.

Optimizing Grinding Process

To achieve the best cause coffee prep work, maximizing the grinding process is vital. The work dimension substantially influences extraction, taste, and overall high quality of the brewed coffee. Different brewing methods call for details grind sizes; for circumstances, espresso demands a great work, while French press demands a crude appearance. Understanding the relationship between work dimension and brewing method is the very first action in optimization.

Furthermore, keeping an eye on the grinding rate can optimize the procedure. Slower grinding commonly creates less heat, protecting delicate flavors and aromas. Conversely, much faster grinding might generate excessive heat, adversely influencing the coffee's quality.

Upkeep and Care Tips

Appropriate maintenance and treatment of industrial coffee mills are important for making certain ideal performance and longevity. Regular cleansing is the foundation of upkeep; deposit buildup can influence flavor and grinding next performance. It is advisable to cleanse the grinder after each usage, cleaning down the outside and removing any type of coffee grounds from the burrs.

In addition, examine the grinding burrs for wear visite site and tear. Boring burrs can endanger work consistency, so they ought to be replaced as necessary. Industrial Coffee Grinder. Occasionally adjusting the grinder is also important, as this keeps the preferred work size for different developing techniques

Lubrication of moving parts should be done according to the supplier's specifications, as this minimizes friction and extends the life of the equipment. It is important to use food-grade lubes to guarantee security and conformity with health and wellness policies.

Last but not least, keep the grinder in a completely dry and stable environment to stop corrosion and rust. By adhering to these maintenance and treatment ideas, drivers can improve the effectiveness of their industrial coffee mills while guaranteeing premium result and prolonged operational life.

Roi Analysis

Examining the return on investment (ROI) for industrial coffee mills is vital for companies seeking to optimize their coffee production abilities. A thorough ROI evaluation helps identify the monetary viability of purchasing premium grinders, allowing companies to weigh the first costs against potential gains.

Assess the purchase price of the grinder, including installment and any type of needed modifications to existing infrastructure. High-performance grinders usually lead to reduced grinding time and have a peek at this website enhanced throughput, which can considerably boost efficiency.

Additionally, consider the influence on item high quality. Industrial Coffee Grinder. Superior mills yield an even more constant grind size, which can improve taste profiles and customer fulfillment, eventually driving sales. By enhancing the top quality of the end product, organizations can warrant higher prices, leading to increased profits

Verdict

In recap, a commercial coffee mill plays a critical duty in enhancing both efficiency and product high quality within coffee production. Ultimately, the critical investment in a trustworthy mill contributes significantly to boosted income and competition in the coffee sector.

In the competitive landscape of coffee manufacturing, picking the appropriate industrial coffee grinder plays a critical function in enhancing both efficiency and item top quality. The 2 primary types of mills are blade grinders and burr mills. Within the burr mill category, there are level burr grinders and cone-shaped burr grinders, each with its advantages. Burr grinders are generally chosen over blade mills, as they give a constant grind size, which is vital for ideal extraction and taste.

In recap, a commercial coffee mill plays an essential role in boosting both efficiency and product quality within coffee manufacturing.

Report this page